Background

Masking tape, also known as painters tape, is cream, blue, or other-colored paper tape used for painting and other projects. This tape is made with two layers: a specialty paper base and adhesive. This market has traditionally been dominated by a small number of companies, with one player controlling 70-80% of the global market.

BiOrigin Specialty Products (BSP) identified an opportunity to develop a masking tape base paper for a European based company. While it took another paper company two decades to perfect this product, BSP achieved comparable results on their very first attempt.

Challenge

BSP had already developed and qualified an excellent product for masking tape base paper, but they lacked a buyer. Vyv Duke, a BSP salesman based in the UK with extensive knowledge of the masking tape market, recognized the opportunity to connect BSP with potential customers in Europe.

“A few contacts of mine in the masking tape business were looking for new base paper suppliers,” explains Vyv. “The market was mostly dominated by one company, and there was a strong demand for alternative suppliers.”

Approach

Vyv conducted a comprehensive market survey and introduced BSP’s product to prospective customers in a few key hubs for the European masking tape industry. Initial interest was strong, with manufacturers eager to diversify their supply chains.

Following Vyv’s efforts, BSP engaged in discussions and soon a partnership was formed.

Solution

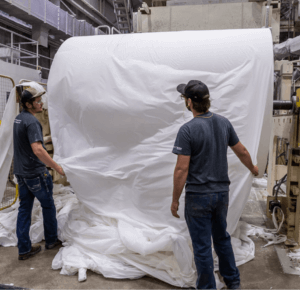

Trials commenced shortly thereafter. The masking tape base was produced on the #2 machine at BSP’s St. Catharines, ON mill. It was then shipped for testing at the customer’s location. Three trial runs were conducted, with the third yielding industry-standard results:

- Trials 1 & 2: Achieved elongation of 6-7%.

- Trial 3: Reached 13% elongation, meeting industry standards.

“Our first trial straight out of the box was as good as the competition—and it’s taken them 20 years to get there,” Vyv recalls. The trials also confirmed the product’s ability to meet technical requirements, such as porosity, latex saturation, and elongation retention through various stages of production.

Results

BSP’s product performed exceptionally well, receiving positive feedback from the customer’s machine operators. The base paper passed initial aging tests, simulating 30 days of product life, and was deemed suitable for general-purpose masking tape. Further refinements are underway to meet the standards of the professional market.

Impact

This partnership has positioned BSP as a viable alternative supplier in a highly consolidated market. The successful trials not only satisfied immediate customer needs but also opened doors for BSP to expand into additional markets.

“There’s a lot of technical nuance in getting the paper to perform throughout the production process, and we hit it out of the park straight away,” Vyv celebrates. “This success was really appreciated by everyone and has set the stage for future growth.”

Conclusion

BiOrigin Specialty Products’ swift and effective entry into the masking tape base paper market highlights the company’s technical expertise and market adaptability. By leveraging strong industry relationships and innovative solutions, BSP has demonstrated its ability to challenge industry giants and establish itself as a trusted partner in the global masking tape market.

PREVIOUS

PREVIOUS